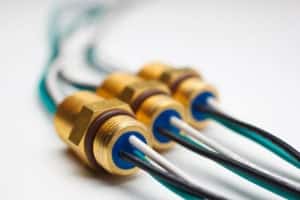

Quality cable & wire harness manufacturing from Salt Lake Cable & Harness

We are your trusted cable and wire harness manufacturer, fully committed to delivering high-quality products to our customers. By monitoring every step closely throughout the production process we ensure that the cable assemblies and wire harnesses are built to your specification.

Our Quality Control team inspects every assembly to ensure customer specifications have been met. In addition, we can provide documentation as objective evidence that the assemblies meet the requirements.

Our commitment to quality includes the following:

- A dedicated Quality Assurance team with a Director of Quality

- All quality inspection teams are IPC certified

- Retaining RoHS, AS9100, and ISO 90001 certification

- Annual audits performed by independent registering bodies and customers.

An excellent & straightforward process for Wire Harness & Cable Assembly projects

Salt Lake Cable & Harness has extensive experience helping customers bring their vision, concepts, and designs to life. The process that we follow for all cable assembly and wire harness projects includes the following:

- Customers providing us with a product design or drawing.

- Review of the product concept for component compatibility and manufacturability.

- Feedback provided to the customers for potential design improvements.

- Prototype / First Article builds and Production builds.

Our production capacities range from prototype builds to full-scale, high-volume production quantities. In general, our projects range from single piece builds to 10,000+ order quantities.

Why choose Salt Lake Cable & Harness?

For over 35 years, Salt Lake Cable & Harness has provided excellent products and services to our clients and customers. Working with us means you can experience a plethora of benefits, which include:

- Extensive engineering knowledge: Our team is comprised of the best and most highly educated engineers and technicians.

- Superior products & service quality: We work with your team from begining to end of the project to ensure that all your needs are met. With our quality service, we have consistently created products that meet or exceedthe highest quality standards in the industry.

- Quick turnaround: We offer fast delivery of prototypes.

Working with us means you only get the best services. At the same time, you receive results that will exceed your expectations.

Experts in cable & wire harness assembly applications

Cable assemblies and wire harnesses are our specialties. We will do our best to bring you exceptional results. Our products are some of the best in the industry. You can count on us to deliver products you can trust.

Salt Lake Cable & Harness works with customers closely, and we will answer all questions you might need regarding your orders. Additionally, we will work with you to make changes to your design while providing you the quality product you envisioned.

If you need more help understanding our process, please contact us now. We will be happy to explain how our process works.